JLR Technology is the new entity taking over from where our previous company Saatech Systems left off. As the founder of Saatech Systems Pty Ltd , John Reid, decided in 2020 to start JLR Technology, a business with a primary focus on just two different technologies, PowerSAW sawmill cutting pattern software, and sales of ScanMeg LED photocells and laser scanners.

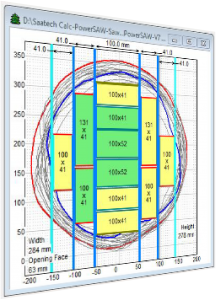

In 1995 we began the development of the predecessor of PowerSAW, and launched the product (then called the Saatech Calculator) at the Hannover Ligna Fair in 1999. In 2023 it is still the creator of PowerSAW software, who is continuing to develop, market, and to support the program. Our PowerSAW package, remains the most widely used cutting pattern creation and analysis software in the world.

JLR Technology are the Australian sales agents ScanMeg. We market ScanMeg single point laser sensors, laser and LED scanning heads, systems, and LED Area photocells for sawmills. Our predominant markets are Australia and New Zealand. We also provide a portal for service and repair of these products. This website enables convenient access to downloadable material such as product data sheets, user manuals, and technical references, particularly in relation to ScanMeg sensors and photocells. We have an unbroken association with ScanMeg for nearly 20 years.

Our business is based on an extensive accumulated knowledge and experience of contemporary high-capacity sawmilling operations, which particularly includes the engineering and technology used in these operations. This has been accrued both from working within some of the most successful sawmills in the country prior to the commencement of Saatech in 1987, and since then as developers, manufacturing of ProScan Log Sorting laser scanning systems equipment suppliers, and consultants to the industry.

Saatech Systems

Saatech Engineering Pty Ltd was formed in 1987 to provide an engineering consultancy service to the plantation-based sawmilling industry. In 1995, Saatech Systems Pty Ltd was incorporated to design, develop and market other Saatech developed products such as ProScan log scanning, sorting and revenue systems; PowerSAW cutting pattern simulation & analysis software; SawCAM green mill simulation software; a range of specialised mechanical handling and processing systems for sawmills; and the Saatech Modular-Sorter planermill sorter-stacker system.

Since 2005 we have been supplying the timber industry with specialised photocells and laser sensors designed and developed by Canadian companies, ScanMeg Inc. and LMI Technologies.

ScanMeg Photocells for Sawmills

ScanMeg Inc of Québec, Canada, manufacture photocells and scanners that are specially designed for - and ideally suited to - the tough environment and reliability demands of sawmills and similar industries. No other sensor company has so single mindedly focused on developing special sensors for just one industry category - the lumber (timber) industries.

Due to an ongoing commitment to R&D, ScanMeg have created a broad range of unique and very rugged sensing and measuring sensors for numerous sawmill applications. Many of their products, such as the P-type Area Photocells, have, for example, revolutionised control of log gaps in debarkers, chipper-canters, twin & quad reducer primary and secondary breakdown machines This is also the case and in drymills, where board gap control is absolutely critical, particularly in the modern planermill where planing feed speeds are commonly very high.

But the ScanMeg product range also extends to include IR light curtain scanners, and a number laser single-point and laser-line sensors. These sensors feature the same ease of setup and connectivity as the P-type Area Photocell. Mill applications using ScanMeg sensors are very simple for your mill electricians to install, configure, and to integrate with the mill PLC.

While the original design focused on the challenges posed in sawmills, ScanMeg sensors are equally at home in a myriad of other manufacturing enterprises.

Note: this website is in the process of being updated.

Order your 15-day PowerSAW trial

World's most popular sawmill cutting pattern software

If you  wish to trial PowerSAW just click the button below.

wish to trial PowerSAW just click the button below.

Be sure to tell us about the type of sawmill you have; ie, a symmetrical cutting log breakdown machine, such as a twin saw, reducer quad saw, a HewSaw, or if you need to create and analyse saw patterns for a carriage line. PowerSAW is very flexible but the technique using the software is slightly different for different sawline types.

Your advice with mill type and configuration information helps us advise you on the best PowerSAW usage practice for your sawmill. While this saves us time, more importantly it saves you time and gets you using the PowerSAW trial very quickly.

LMI Technologies Sensors for Sawmills

Founded in 1979 in Vancouver, BC, LMI Technologies Inc is now part of the TKH group—an internationally operating, innovative technology company with its registered office in the Netherlands.

LMI Technologies products were introduced to the Australian market by Saatech Systems in the early 1990s. In the following 20 years we achieved sales to most large Australian sawmills of our ProScan 3D log scanning and revenue systems, all featuring LMI laser scan heads.

Although we no longer represent LMI sales, or manufacture 3D scanning systems, we provide a repair service for popular legacy laser type SLS5000 series sensors.

In particular, we provide a fixed price repair of the LMI SLS5000-325/400-AL sensor, which remains widely used in the aluminium mill industry. Please use the button below to contact us, or visit our store to enquire and/or purchase a repair service.